DESTRUCTIVE TESTING

- Bending Test

The test is made to determine the behavior of the materials when the forces causing the bending are under influence. The welded joints are made to determine the ductility in the weld surface or near the surface.

The steps of the test are as follows;

Material is placed between the two supports.

The midpoint of the material is suppressed with a force of magnitude.

Care should be taken to ensure that the part is not completely destroyed in order for the test to yield a healthy result.

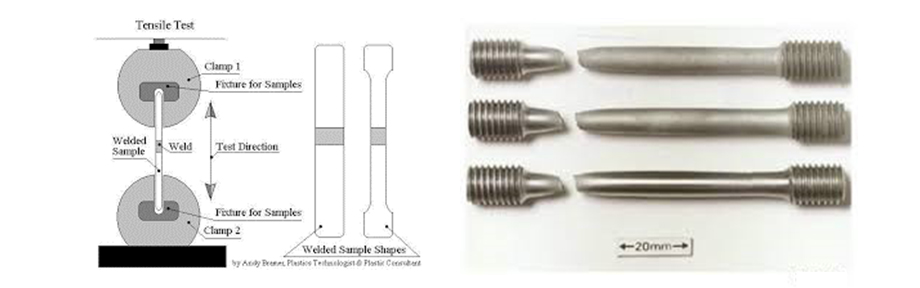

- Tensile Testing

It is a test made to measure the resistance of the materials against the applied force against the breaking. It is used to determine the mechanical properties of the material.

The steps of the test are as follows;

The material is placed between the jaws of the towing device.

With the help of movable jaws, the material is continuously exposed to an increasing force.

Permanent plastic deformation occurs in the material when the force applied to the material exceeds the yield strength, which is the elasticity limit.

This plastic change-out material gives the neck from a certain point and after a while it breaks away from the neck area.

The force and unit elongation values displayed on the instrument screen are read.

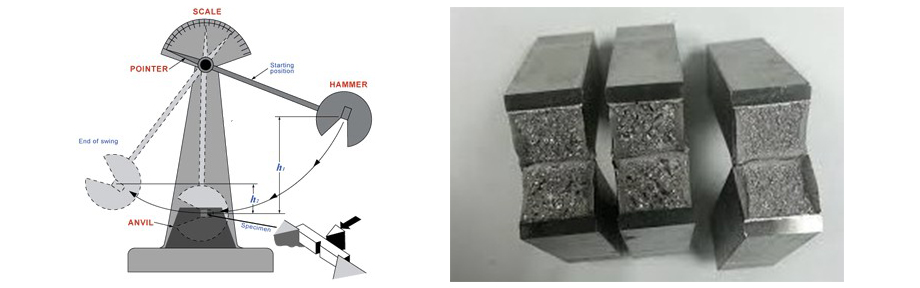

- Charpy Impact Testing

Tests are made to measure impact strengths or fracture energy in the event of a notch formation of materials.

The steps of the test are as follows;

A notch is opened on the material to be tested.

The material is connected horizontally to the test table.

The hammer is released in the notch direction only from the opposite plane of the notched plane.

Hammer breaks material.

In the Charpy Impact Testing, 3 notch types are used, U, V and Key Mouth.

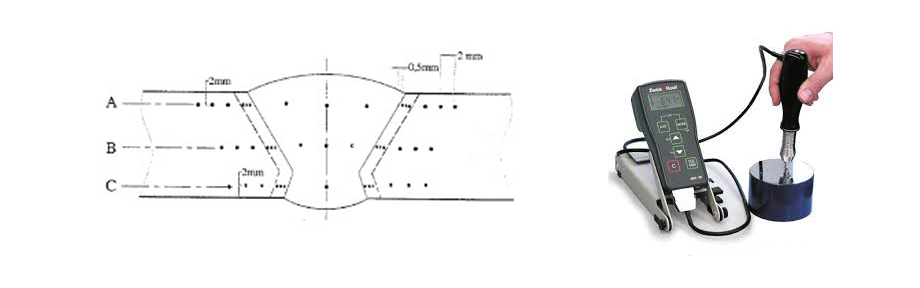

- Hardness Testing

It is a test made to measure the resistance of the material to plastic deformation, that is, the permanent damage. The suitably selected hard tip will leave a mark on the material when it is submerged under the applied load. The rigidity of the material is inversely proportional to the magnitude of this permit.

In this test method, a square square pyramid with a peak angle of 136 ° is used as a pressing element.

The steps of the test are as follows;

The material is pressed with F load.

The diagonal permissive diagonals left by the pyramid tip are measured.

Hardness values are calculated using the calculated average diagonal length.

The advantage of Vickers stiffness is that it makes highly accurate readings and only one type of sinker tip is used for all metal and treated surfaces.

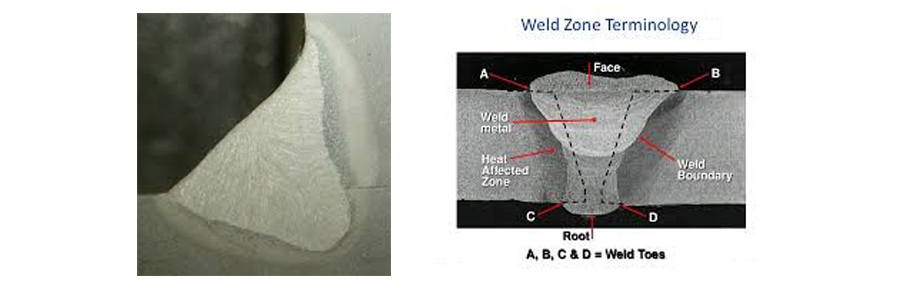

- Micro & Macro Examinations

MACRO EXAMINATIONS: A test made by inspecting the surface of a sample taken from the welding area with a chemical combination by microscope after magnifying it 10 times with the help of chemicals.

With this test method, you can determine;

Throat height in corner welds

Effective throat height

Source penetration in fore and aft corner welds

Cracks, pores, etc. Discontinuities

MİCRO EXAMINATIONS: In a welded joint, the surface of a sample taken from the weld zone is macerated and examined with a microscope under a microscope. As a result of this test, the mechanical properties of the pleasure zone are determined.

Unlike the macro test, the metallographic preparation of the sample requires more attention.

With this test method, you can determine;

Grain size

Grain structure

Phase changes resulting from welding operation

Micro cracks